How do I complete the Precautionary Safety Measures section of the Hot Work tab in the Permit to Work (PTW) system, in OHS Online?

Okay! Let's take a closer look at this section. Once the hot work hazards, for the work being done, have been identified, the necessary checks and controls to any hot work performed is safe, must be confirmed and checked.

The Precautionary Safety Measures section is where these safety measures are determined and confirmed. The Permit Issuer and Permit Requester work through and confirm the safety measure checks and must make sure that these checks are in place before any hot work starts. This section consists of two parts:

1. General Precaution Measures - These are standard precaution measures which should be in place for the work being done. These will display automatically, as a default in this PTW tab and any options which are relevant to the work being done must be checked as YES and any options not relevant to the work being done must be checked as NO.

2. Specific Precaution Measures - These are particular precaution measures which should be in place, when a specific hazardous hot work aspect of the work being done is present. These will display (be active) when a particular height work hazard in the Work Environment section, is selected. If the hazard is not selected, its associated specific precaution measure will not be displayed (remains inactive).

Let's look at the general precautionary measures a little more closely:

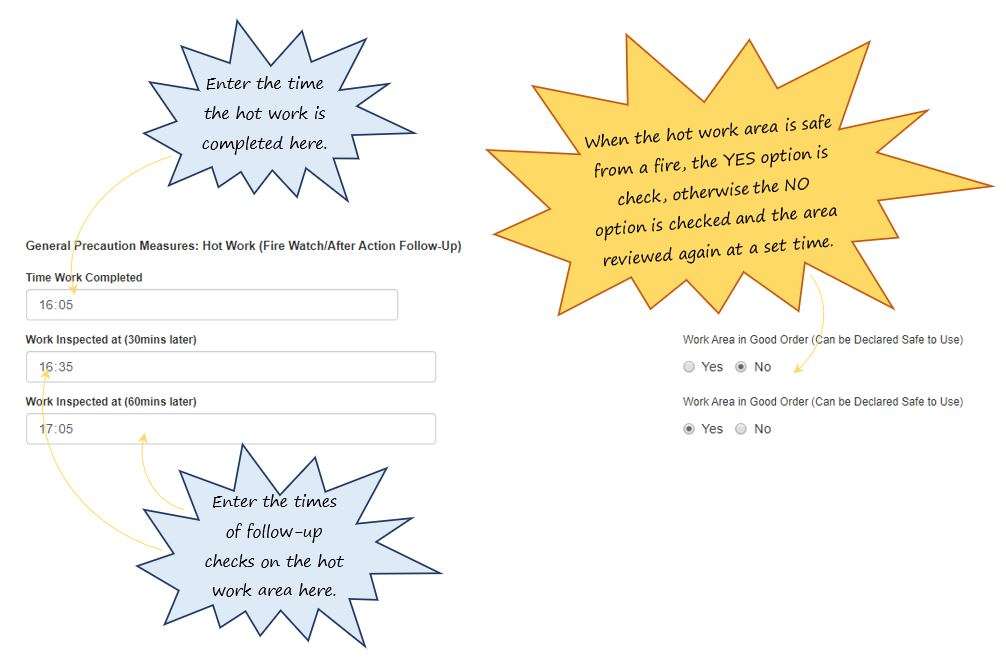

In addition to the general precaution measures for hot work, this section also includes a fire-watch check, which allows a post hot work fire-watch check to be made and recorded:

Now, let's look at the Work Environment hazards of the Hot Work tab more closely and see what specific precautionary measures their checks will affect:

1/. Welding (wet/metal contact) Hazards - This becomes a relevant hazard where welding in wet environments or environments where large metal contact is very probable. Both of these environments need specific checks in place to reduce the likelihood of electrocution through welding electrodes misuse or accidents. This hazard needs to be checked as YES in the Work Environment section. When this is checked in the Work Environment section, this set of specific precaution measures will display:

2/. Confined Space Entry Hazards - This becomes a relevant hazard where any hot work requires entry into a confined space to be done. When this option is relevant, it must be checked as YES. This means that the Confined tab must also be made active and then the hot work details recorded in conjunction with the Confined tab of the PTW, where the hot work hazards are recorded here and the confined entry details recorded in the Confined tab.

3/. Vessel / Tank/ Piping Hot Work Hazards - This becomes a relevant hazard where any type of hot work takes place on a vessel, tanks or piping, where there is a high probability that combustible, flammable or explosive chemicals may have been contained in the vessel type or where it is not known what may have been in the vessel type. These situations need specific checks in place to prevent the likelihood of an explosion or fire breaking out when the work takes place. These hazards need to be checked as YES in the Work Environment section. When these are checked in the Work Environment section, the vessel precaution measures for a vessel will display. These vessel precaution measures are an additional set of measures which need to be checked and confirmed, in order to ensure that complex hot work is conducted safely:

Leave a comment