What is the importance of the Confined tab in the Permit to Work (PTW), in OHS Online?

A very important question! The Confined tab of the PTW must be selected whenever any confined space entry is included in any of the work processes the contractor does. Confined space entry work is considered 'high risk' because every year persons are killed or seriously injured either in confined spaces themselves or in attempting to rescue persons trapped in confined spaces.

CONFINED SPACES AND THEIR DANGERS

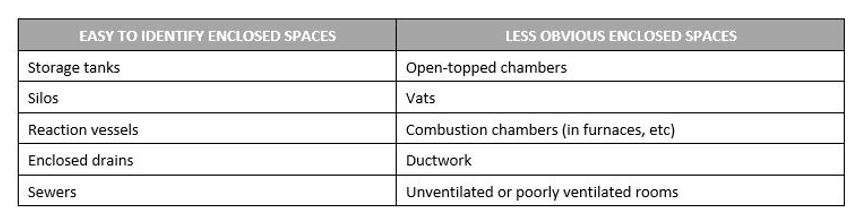

Confined spaces are any spaces of an enclosed nature where there is a risk of serious injury or death from dangerous conditions by entry into the enclosed space or where there is a risk of serious injury or death from hazardous substances contained within the enclosed space. Some confined spaces are easy to identify as they are enclosures with limited openings; others are less obvious but because of their nature, they can be just as dangerous:

Confined spaces can present a number of different dangers to a person entering them:

1. Lack of oxygen (oxygen deficient environment) - these conditions can occur where there is a reaction between some soils and oxygen in the atmosphere; where groundwater reacts with chalk or limestone, producing carbon dioxide and displacing oxygen inside the space; in ships' holds, freight containers, lorries, etc, as a result of the cargo reacting with oxygen inside the space; inside steel tanks and vessels when rust performs.

2. Poisonous (toxic) gas, fumes or vapours - these can build up in sewers, manholes or in pits connected to the system; enter tanks or vessels from connecting pipes; leak into trenches and pits in contaminated land, such as old refuse tips and old gas works.

3. Liquids and solids - these can suddenly fill the space or release gases into the space when disturbed; free-flowing solids (such as grain) can partially solidify in silos and then unexpectedly collapse.

4. Fire and explosions - these occur from flammable gas or vapours present in the space or from excess oxygen present in the space.

5. Substance residues - these are residues left in tanks or vessels which remain on the internal surfaces of the space and give off gas, fumes or vapours.

6. Dust - when this is present in high concentrations (such as four, sugar, etc), it can become highly flammable and even explosive.

7. Hot conditions - these lead to a dangerous increase in body temperature and an increase in loss of body fluids.

NOTE: It is important to understand that in some cases these conditions may already be present, however, in other cases these dangers can arise from the work being done inside the enclosed space:

1. Machinery - machinery may be used which requires special precautions attached to its use; dust extraction on a portable grinder or specific precautions to prevent electric shock.

2. Vapour generation - these can arise from welding work or when using volatile, flammable solvents or adhesives.

THE DANGERS OF AN EXPLOSIVE ATMOSPHERE

Explosive atmospheres occur when there is a mixture of dangerous substances or substances (gas, mist, dust or vapour) with the air, which has the potential to either catch fire or explode. An explosive atmosphere may not always explode but it may well catch fire, causing the flames to spread rapidly and, in a confined space, this could be fatal. Additionally, in a confined space, the rapid spread of flames or the rise in internal pressure may well lead to an explosion.

IMPORTANT CONSIDERATIONS ASSOCIATED WITH CONFINED SPACE ENTRY

The high risks associated with confined space entry mean safety considerations and precautions need to be made and put into place to ensure any confined space entry work is carried out safely:

1. Isolation checks - often the confined entry is into vessels or tanks which form part of a system. In these cases, it may be important to isolate the vessel or tank mechanically from the rest of the system. Alternately, there may be a need to isolate the vessel or tank electrically, to prevent the risk of electrocution.

2. Cleaning - where vessels or tanks contain residues, it may be necessary to clean these out before confined entry is made, to ensure no fumes or vapours are generated.

3. Air testing - often where the contents of the enclosed space have contained flammable contents or unknown contents, the testing of the air should be made to ensure it is safe to work in and more importantly, to ensure any work conducted does not result in a fire or explosion. Continuous monitoring of the air is good practice, even while the work is commencing.

4. Provision of breathing equipment - the correct breathing equipment needs to be determined and allocated for any confined entry work.

5. Communications - a system of communication needs to be put into place between the persons inside the confined space and a contact on the outside, who can react in the event of an emergency.

6. Emergency provisions - arrangements need to be made to provide for emergency situations. These should cover equipment, training and practice drills. Lifelines, attached to harnesses, which run back to a point outside the confined space, need to be included for confined entry work.

The Confined tab helps to ensure that formal checks are made and associated safety precautions are taken for any confined space entry work, in order to ensure the confined space work is conducted under safe working conditions. Through these measures, confined space hazards and precautions are documented and recorded, prior to confined space work taking place.

Leave a comment