In OHS Online, how do I complete a concentration measurement type for a mixture of components in the Measurement Details section in the vessel specific precautions section?

Ahh yes, recording concentration measurements! These can be a bit trickier because the contents being measured may be a single component (ethane gas) or they may be more than one component (a mixture of methane and air). When there is more than one component present in the contents, these can be potentially more dangerous and so each component may need to be measured to ensure that the contents are overall safe. Let's look a mixture of components which need measurement in this case.

Now let's look a mixture component measurement, using two components to illustrate the example (more than two components would simply be a case of adding the extra number of components). When the concentration measurement type is selected, readings are entered, which relate to the concentration of each component making up the contents in the vessel. These readings can be recorded in either parts per million (ppm) or percent (%) and should be at values safe for either exposure to persons working or where the likelihood of a fire or an explosion is remote, in order to ensure the work being done is safe.

The actual concentration measurement type looks as follows (using the percent concentration type as our example):

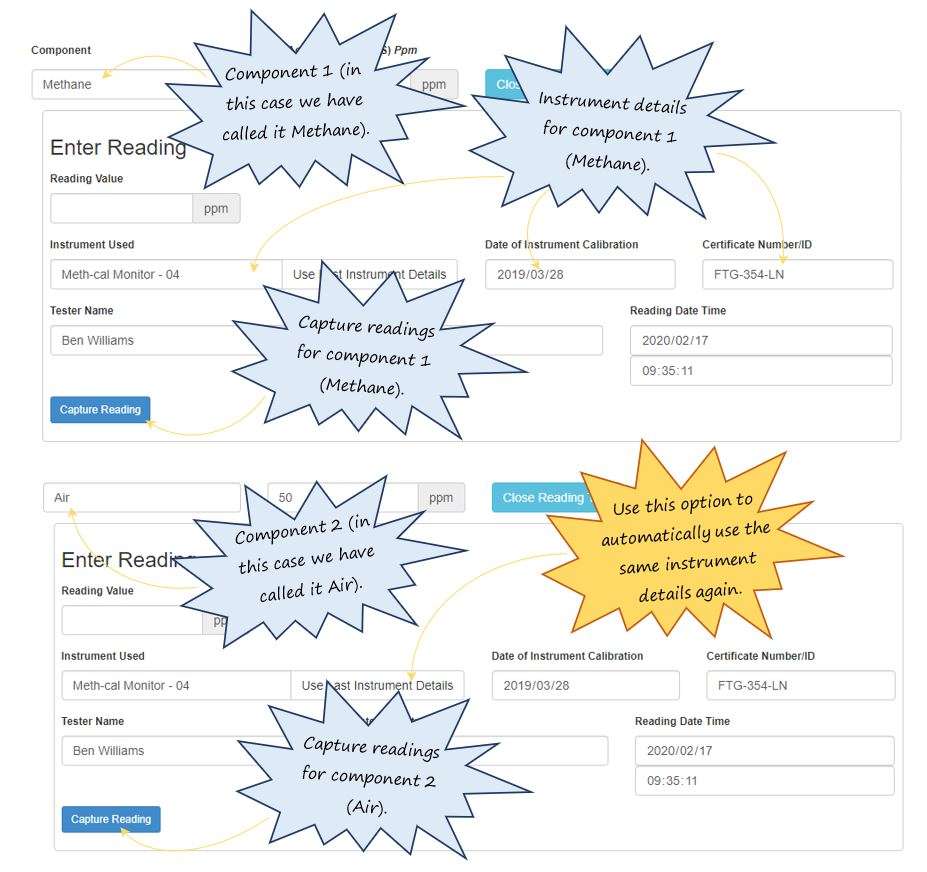

Once the initial details of the measurement type have been entered and the number of components, making up the mixture, added, the actual readings now need to be added. Each component has its own ENTER READING VALUE button. Clicking on the relevant button will open the readings section for that component, allowing the measurement details for that component to be entered:

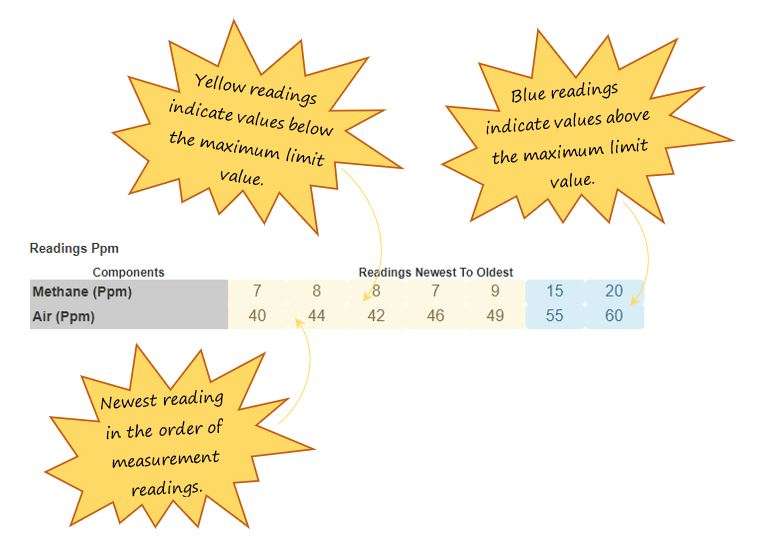

Once the instrument details have been entered for each component, the actual readings need to be recorded for each component. Each reading is recorded by entering the reading value in the Reading Value field and then clicking on the CAPTURE READING button. This process is repeated each time a reading needs to be recorded, until the reading values stabilise and show consistently at the desired measurement limit value. The recorded measurements will then display in a row underneath the last component, with each component displayed underneath one another:

Once the reading values for each component have stabilised below the maximum limit value and the readings indicate the stability of each, then the contractor and client can be confident that the concentration of the contents (and their components) of the vessel are now at a level which is safe for work to continue.

Leave a comment